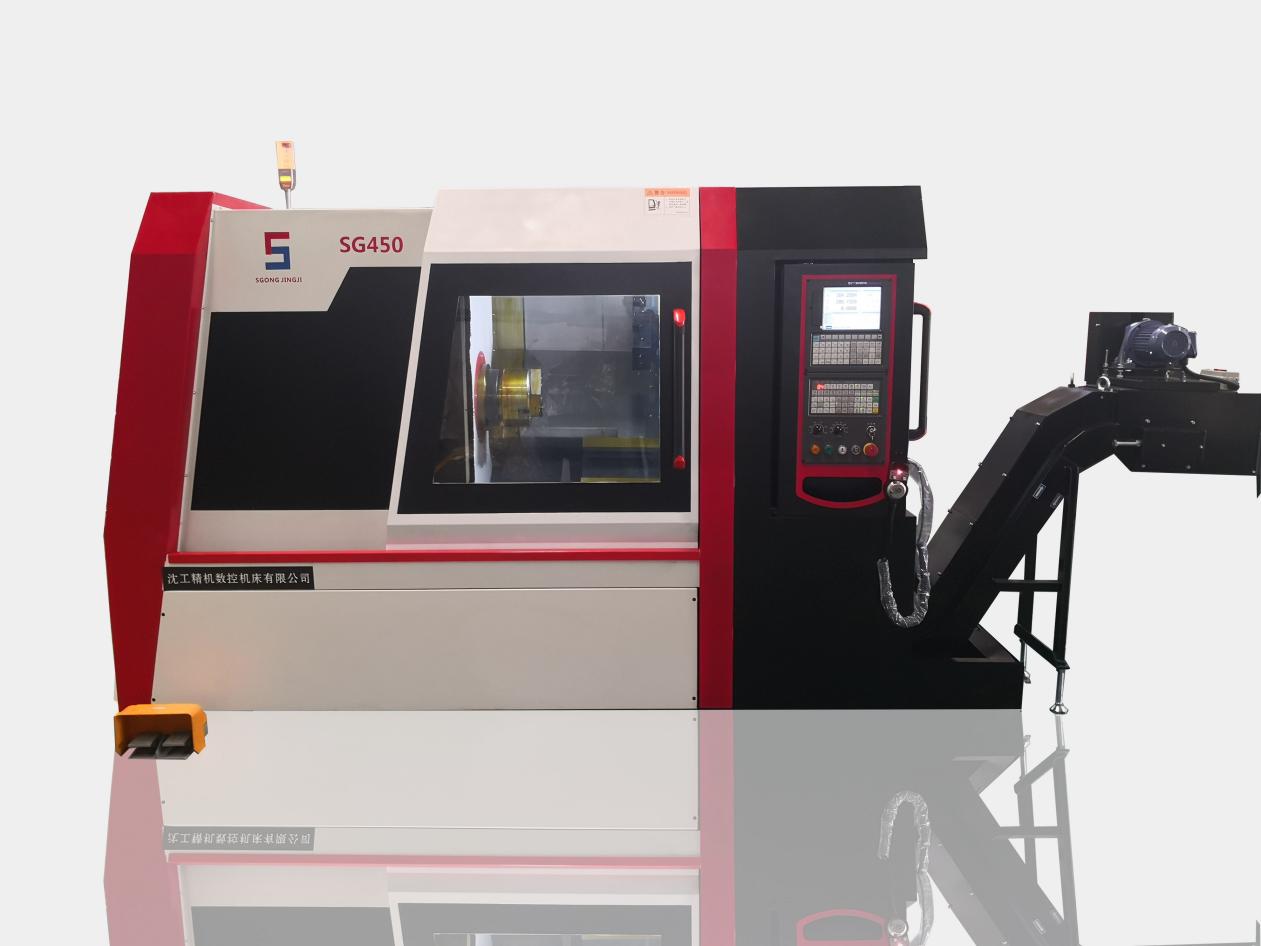

Are you here:Home > Products > CNC lathe > Inclined bed CNC lathe

parametermodel

SG450/SG450W

SG500/SG500W

SG550/SG550W

Max.Turning diameter over

bed(mm)

Φ450

Φ500

Φ550

Max.cutting Dia.for axle/disc

parts(mm)

Φ200/Φ300

Φ280/Φ400

Φ300/Φ480

Max.turning length(mm)

370

500

700

Chuck size(inch)

8

8

10

Spindle nose

A2-6

A2-8

A2-8

By bar diameter(mm)

Φ52

Φ52

Φ75

Tail seat sleeve stroke(mm)

80

100

100

Max.spindle speed(rpm)

4000

3000

3000

Fast moving speed(m/min)

25/25(X/Z)

15/20(X/Z)

15/20(X/Z)

Max.X axis travel(mm)

240

280

280

Max.X axis travel(mm)

450

600

850

No.of tool post station

8

8

10

Tool change time(s)

0.3

0.3

0.3

Outside Dia.Cutting tool shank(mm)

25×25

25×25

25×25

Spindle motor power (30

minutes/continuous)

11

11

15/18.5

Servo motor torque( X/ZNm)

15/15

15/15

18/18

Bed structure

30

° oblique back

30

° oblique back

30

° oblique back

X/Z repeat positioning accuracy

±0.003mm

±0.003mm

±0.003mm

X/Z position accuracy

±0.005mm

±0.005mm

±0.005mm

Net weight(kg)

2900

3800

4200

System optional(GSK.SYNTEC.FANUC.MITSUBISHI.SINUMERIK,etc.)

If you have any suggestions for our products or services, please leave me a message in a timely manner!

Contact us is the way to solve the problem