Technical parameters of CNC lathe CK6150

|

Project

|

Technical

Specifications

|

|

Rotating diameter of large workpiece on the bed

|

Φ500mm

|

|

Rotating diameter of large workpiece on the trailer

|

Φ290mm

|

|

Length of large workpiece

|

1000/1500mm

|

|

Main spindle speed range

|

3rd

gear, 25~1600rpm

|

|

Spindle through-hole diameter

|

Φ82mm

|

|

Rail width

|

390mm

|

|

Main spindle head form

|

D-8

|

|

Taper of spindle inner hole

|

1:20

|

|

Knife holder number

|

4-station

electric knife holder

|

|

Tool section specifications

|

25mm×25mm

|

|

Motor small setting unit

|

(Z)

Vertical 0.001mm, (X) horizontal 0.001mm

|

|

Knife bar fast forward speed

|

(Z)

Longitudinal 10m/min, (X) transverse 8m/min

|

|

Taper of the inner hole of the tailstock sleeve

|

MT5

|

|

Large movement distance of tailstock sleeve

|

150mm

|

|

Main motor power

|

7.5KW

|

|

Net weight of lathe approximately

|

2700kg

|

Main features of CNC lathe CK6150

1. 24 level gear shifting, high turning torque, high machining efficiency, and high precision,.

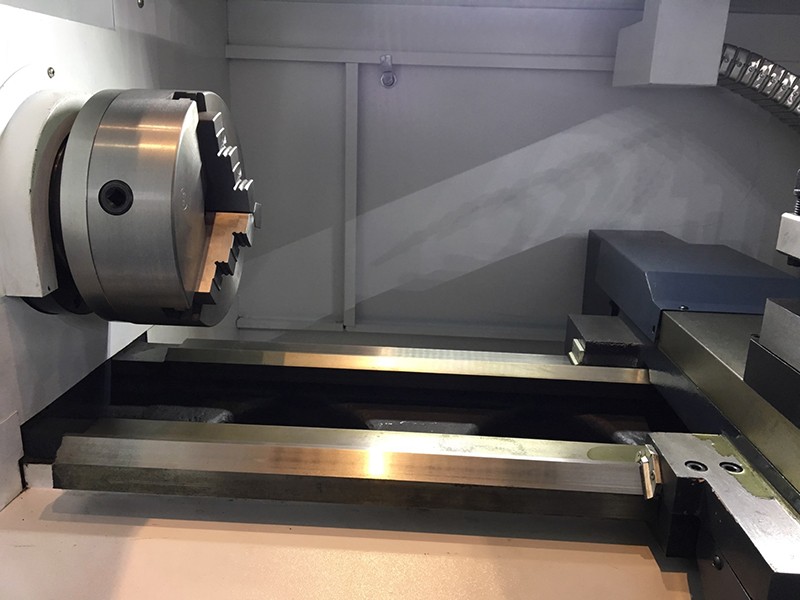

2. Increase the diameter of the main shaft by 82mm.

3. The bed width is 420mm.

Main configuration of CNC lathe CK6150

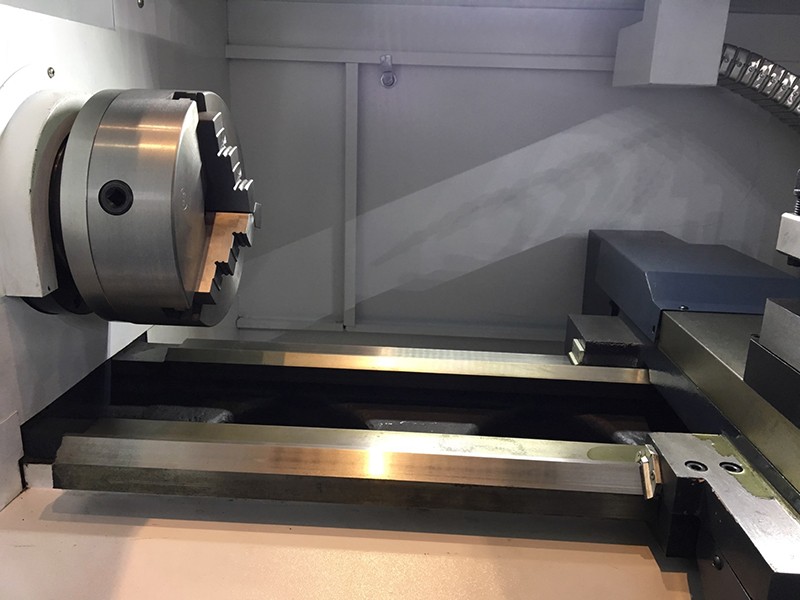

⑴ Control system: Guangshu GSK ⑵ Chuck options: manual, pneumatic or hydraulic chuck, etc.

⑶ Tailstock optional: manual

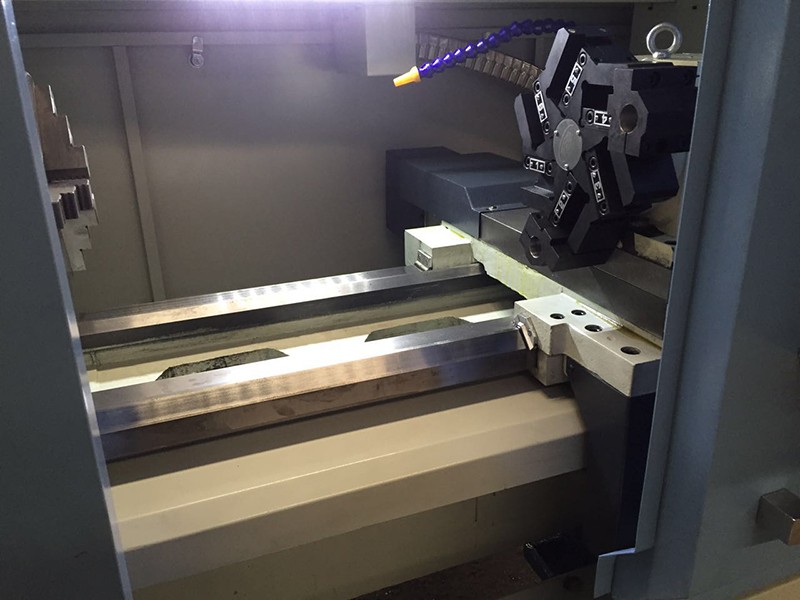

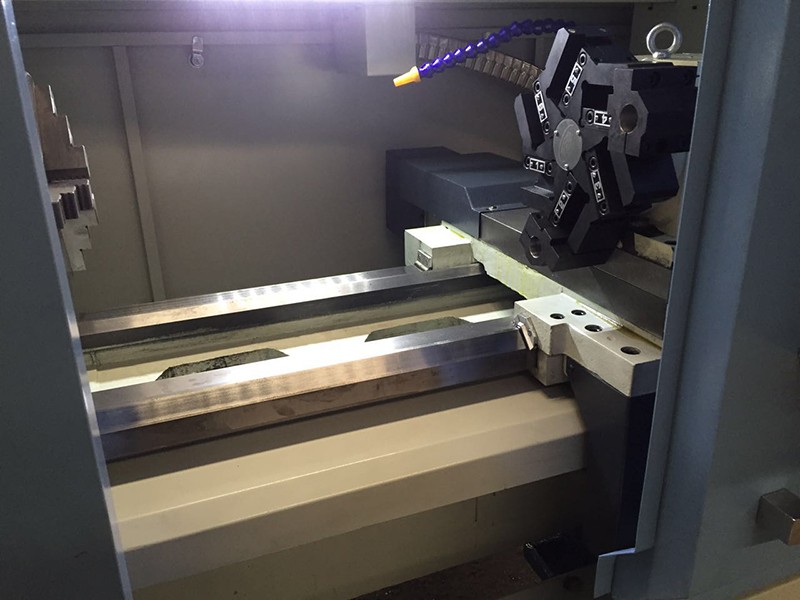

⑷ Electric knife holder: vertical four station

⑸ Lubrication configuration: Automatic oil lubrication system.

Application of CNC lathe CK6150

This machine tool can be widely used for precision machining of valves/plumbing/automotive parts and other hardware components, and can achieve automatic cutting of various products' outer circles/end faces/inner holes/grooves/arbitrary conical surfaces/spherical surfaces and various metric and imperial threads

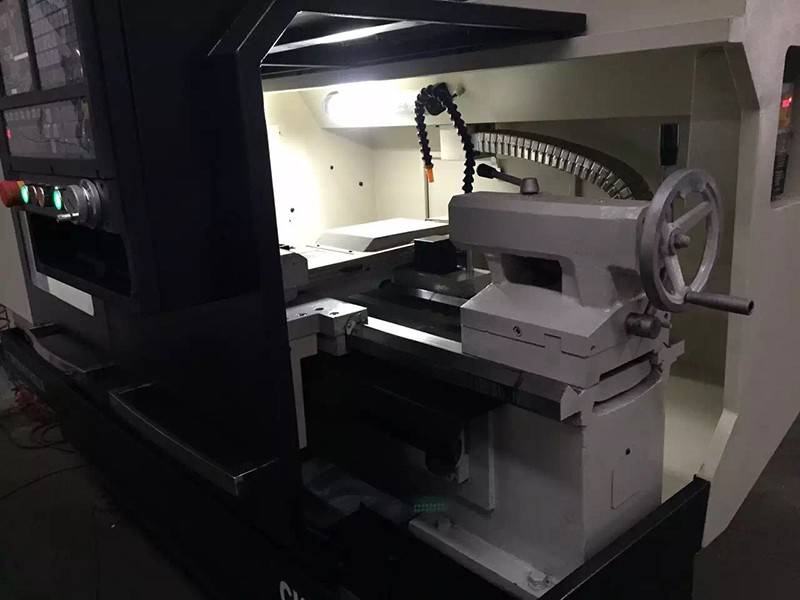

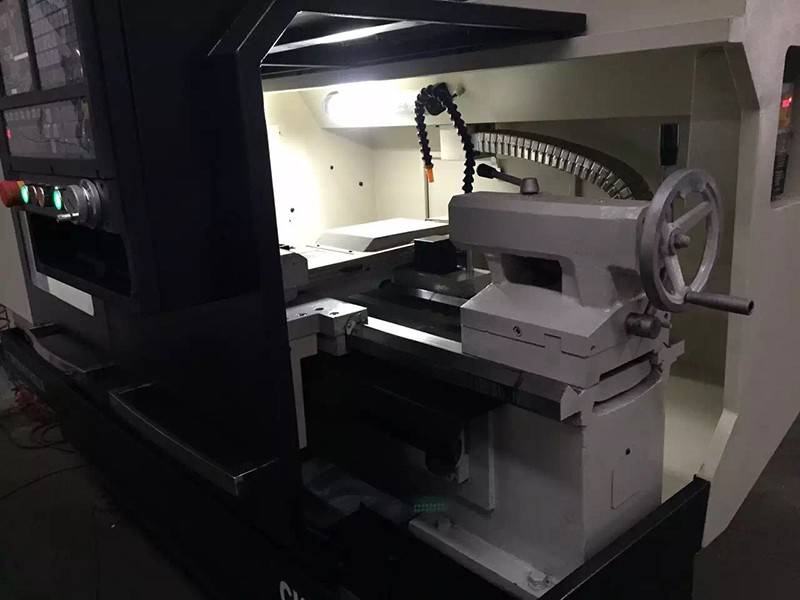

LED work light

Guide rail plastic pasting technology has good dynamic performance and low noise

High quality four - and six station CNC knife holders

High precision tailstock

Premium interior protection, details determine success or failure

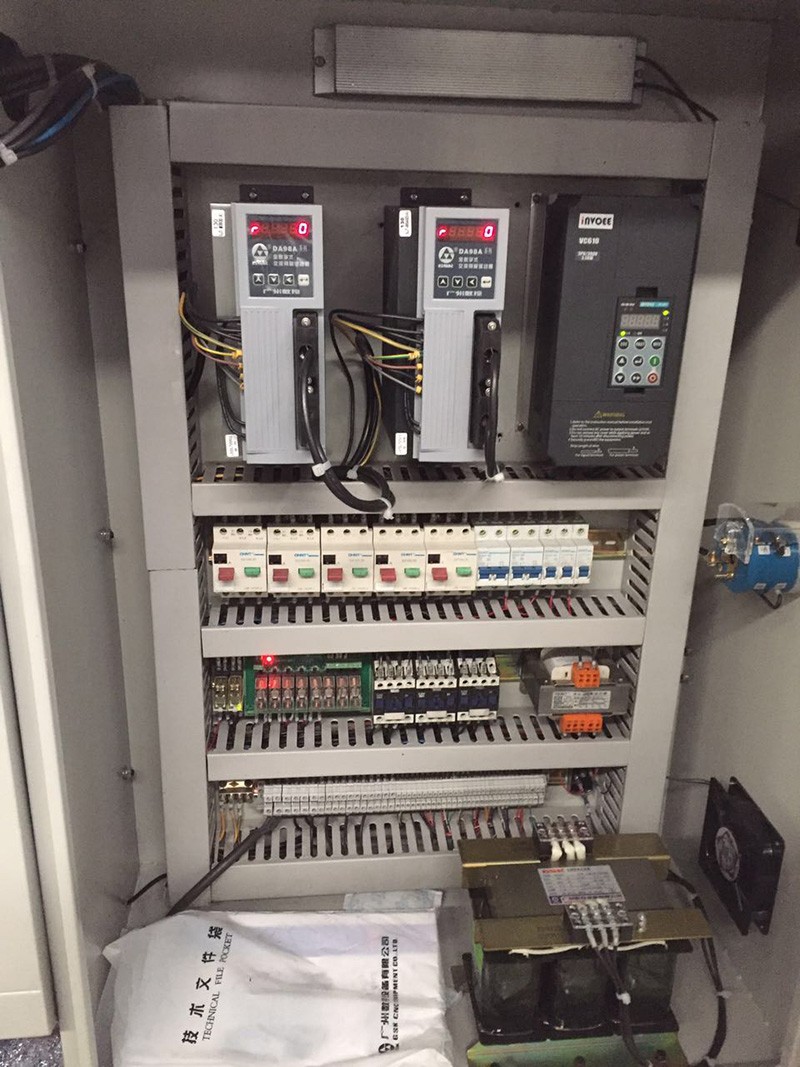

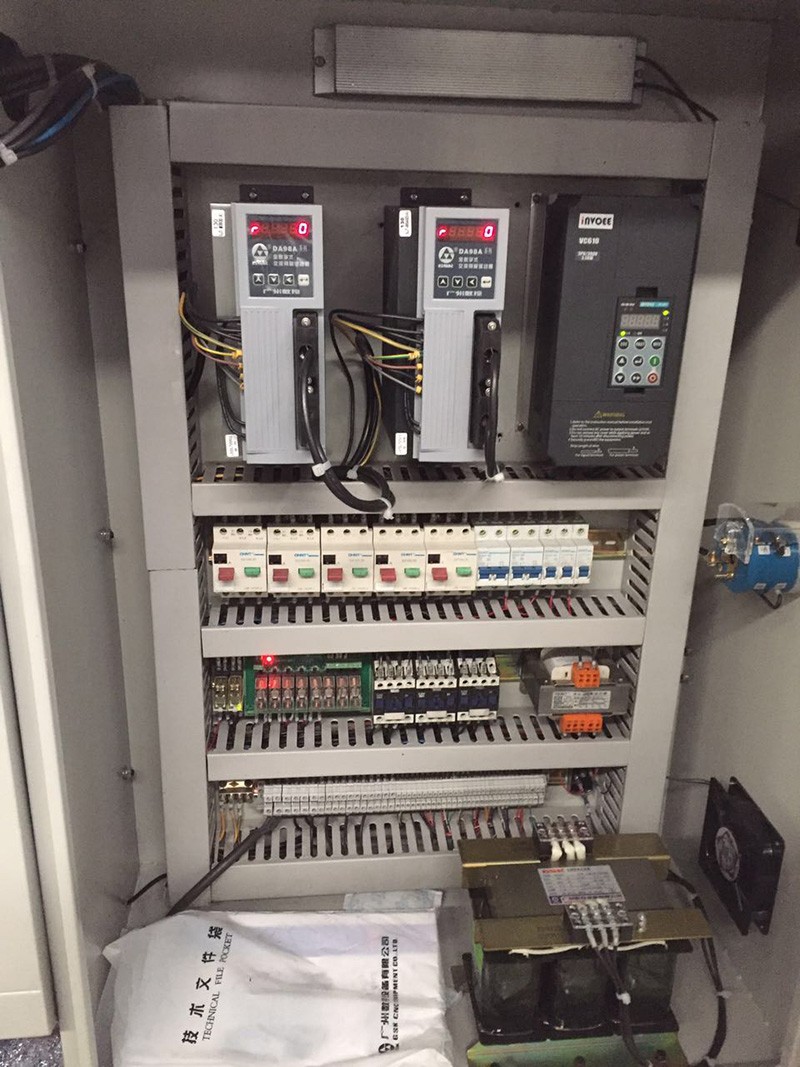

Advanced high-end electrical cabinet

High quality, high rigidity, wear-resistant guide rail

Whole casting bed body with ultrasonic quenching treatment for better rigidity and stability

Company Profile

Shenyang Jingji CNC Machine Tool Co., Ltd. is a modern enterprise specializing in the production of various types of CNC lathes. Our company specializes in producing a series of CNC lathe products, including flat bed and inclined bed CNC lathes, as well as CNC instrument lathes; In addition, we provide specialized CNC machine tool design solutions and production manufacturing; Design and manufacture of various fully automatic CNC machine tools. The main performance indicators of the product have reached the advanced level in China. A professional design team, consisting of experienced professionals with intermediate and senior professional titles in mechatronics technology, integrates our proprietary technology with international and domestic technologies into our products. Technical services, mature technology, attentive service, have gained recognition from a wide range of customers.

Service Items

1. CNC lathes produce CK6136, CJK6140, CK6150, etc., with mature technology that consistently exceeds national precision standards and has received high praise from a wide range of users.

2. CNC instrument lathe: CJK0640, CJK0640H (wire rail model), etc.

3. Slant bed CNC lathes: SG300, SG320, SG360, SG450, etc.

4. A professional design and development team for CNC specialized machine tools (special machines). A powerful specialized equipment design and manufacturing team, tailor-made professional solutions for your products

Contact Us

Wuxi Shengong Precision CNC Machine Tool Co., Ltd

Phone: 15190241652

Landline: 86 0510 88255025

Address: 580 Xida Road, Wuxi City, Jiangsu Province, China

Website: http://www.wxsgjj.cn