The machine tool adopts an integrated casting of the bed body and bed feet, which has extremely low resistance to twisting deformation and high stability.

The guide rail adopts a fully protective structure, which prolongs the service life of the guide rail.

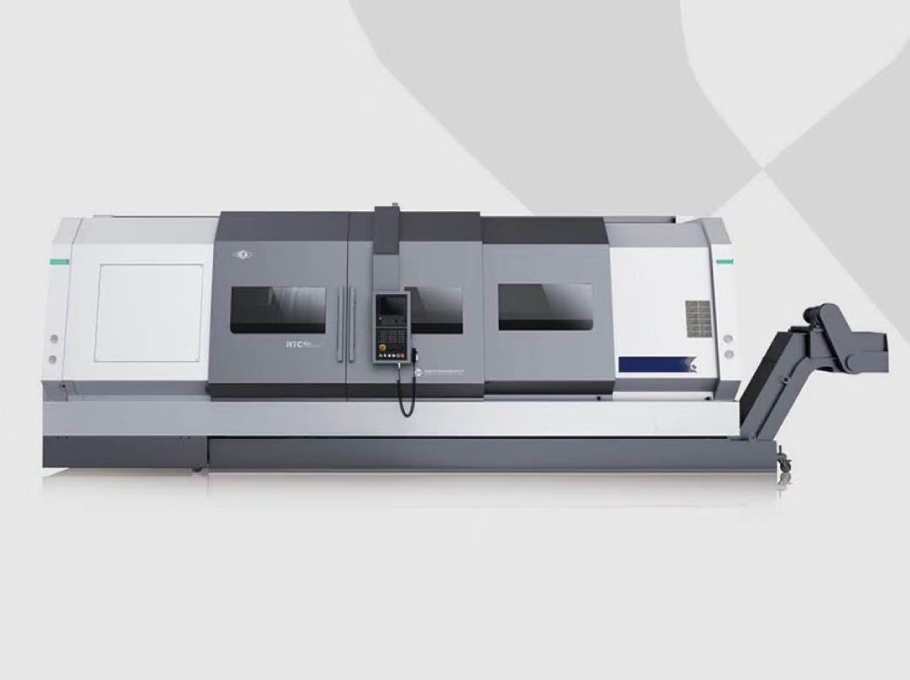

★ Integrated design of electromechanical and hydraulic systems, small size, compact structure, convenient chip removal, and beautiful and elegant appearance.

Reasonable layout and easy maintenance.

The spindle is operated by a servo main motor, achieving stepless speed change.

★ High precision ball screw pair with three-point pre tension structure, high-precision pre tightening nut, high transmission accuracy, can ensure small mechanical errors for a long time.

★ High precision coupling, no slip at high speed and high torque.

The independent lubrication system design of the bed ensures the durability of the moving parts.

The control cabinet adopts a fully sealed device, which isolates dust and water vapor completely. The computer system and circuit parts are kept dry and dust-free, and durable;

The machine tool adopts fully enclosed protection, with a beautiful and pleasant appearance, superior waterproof performance, easy to open sliding doors, flexible and convenient, and safe and reliable.

Company Profile

Shenyang Jingji CNC Machine Tool Co., Ltd. is a modern enterprise specializing in the production of various types of CNC lathes. Our company specializes in producing a series of CNC lathe products, including flat bed and inclined bed CNC lathes, as well as CNC instrument lathes; In addition, we provide specialized CNC machine tool design solutions and production manufacturing; Design and manufacture of various fully automatic CNC machine tools. The main performance indicators of the product have reached the advanced level in China. A professional design team, consisting of experienced professionals with intermediate and senior professional titles in mechatronics technology, integrates our proprietary technology with international and domestic technologies into our products. Technical services, mature technology, attentive service, have gained recognition from a wide range of customers.

Service Items

1. CNC lathes produce CK6136, CJK6140, CK6150, etc., with mature technology that consistently exceeds national precision standards and has received high praise from a wide range of users.

2. CNC instrument lathe: CJK0640, CJK0640H (wire rail model), etc.

3. Slant bed CNC lathes: SG300, SG320, SG360, SG450, etc.

4. A professional design and development team for CNC specialized machine tools (special machines). A powerful specialized equipment design and manufacturing team, tailor-made professional solutions for your products

Contact Us

Wuxi Shengong Precision CNC Machine Tool Co., Ltd

Phone: 15190241652

Landline: 86 0510 88255025

Address: 580 Xida Road, Wuxi City, Jiangsu Province, China

Website: http://www.wxsgjj.cn

|

parameter model

|

SG630

|

SG800

|

Max.cutting Dia.for disc parts

|

Φ550mm

|

Φ700mm

|

Max.cutting Dia.for axle parts

|

Φ350mm

|

Φ500mm

|

Maximum length of processed workpiece

|

1000mm

|

1500mm

|

By bar diameter

|

Φ90mm

|

Φ105mm

|

Max.Z axis travel

|

1000mm

|

1650mm

|

Max.X axis travel

|

320mm

|

365mm

|

X axis rapid movement speed

|

12000mm/min

|

15000mm/min

|

Z axis rapid movement speed

|

15000mm/min

|

15000mm/min

|

Spindle nose

|

A2-8

|

A2-11

|

Spindle nose

|

Φ105mm

|

Φ125

|

Max.spindle speed

|

2000rpm

|

1500rpm

|

X/Z repeat positioning accuracy

|

±0.003mm

|

±0.003mm

|

X/Z position accuracy

|

±0.005mm

|

±0.005mm

|

No.of tool post station

|

8 Servo

hydraulic

|

10 Servo hydraulic

|

Tailstock sleeve bore taper

|

MT-4

|

MT-5

|

Tailstock sleeve Dia.

|

100mm

|

150mm

|

Tail seat movemebt method

|

Saddle drive,

hydraulic locking

|

Saddle drive, hydraulic locking

|

Bitmap

|

22KW servo main

motor

|

22KW servo main motor

|

overall dimensions (L*W*H)

|

4000×2300×2200

|

6200X2500X2500

|

Net weight

|

about 6500 kg

|

about 9000 kg

|

System optional(GSK.SYNTEC.FANUC.MITSUBISHI.SINUMERIK,etc.)

|